In the dynamic landscape of the industrial sector, data analytics serves as a transformative tool, poised to drive operational efficiencies, increase competitiveness, and amplify profitability. This potential is significantly elevated when data analytics is coupled with robust data platforms.

Data platforms play an integral role in the industrial analytics solutions. Acting as a unified infrastructure, these platforms aggregate, process, and analyze data from diverse sources. This consolidation paves the way for extracting valuable insights that fuel informed decision-making and strategic planning within industrial companies.

Data platforms provide a plethora of benefits that amplify the impact of data analytics

- Centralized Data Management: By unifying disparate data sources into a single system, data platforms eliminate data silos. This centralized management leads to a holistic view of operational data, fostering more accurate and comprehensive insights.

- Data Quality and Integrity: Data platforms ensure data is properly cleansed, formatted, and validated prior to analysis. This process heightens data quality, guaranteeing the reliability and actionability of generated insights.

- Scalability: With the expansion of industries comes an increase in data volume and complexity. Data platforms are equipped to manage this growth, allowing companies to scale their analytics capabilities in sync with their operational expansion.

- Security and Compliance: A well-implemented data platform enhances data management and protection, ensuring compliance with data privacy regulations and providing a robust defense against cybersecurity threats.

- Real-time Analytics: Data platforms enable real-time analytics, allowing companies to swiftly respond to changes in operational conditions or market dynamics.

Building upon these data platform advantages, the adoption of data analytics in the industrial context delivers numerous operational benefits:

- Improved Operational Efficiency: Data analytics can pinpoint bottlenecks, streamline processes, and elevate operational efficiency. This leads to waste reduction, quality improvement, and productivity enhancement.

- Predictive Maintenance: By leveraging data from machine sensors, predictive maintenance models preemptively identify potential equipment failures, curtailing downtime and repair costs.

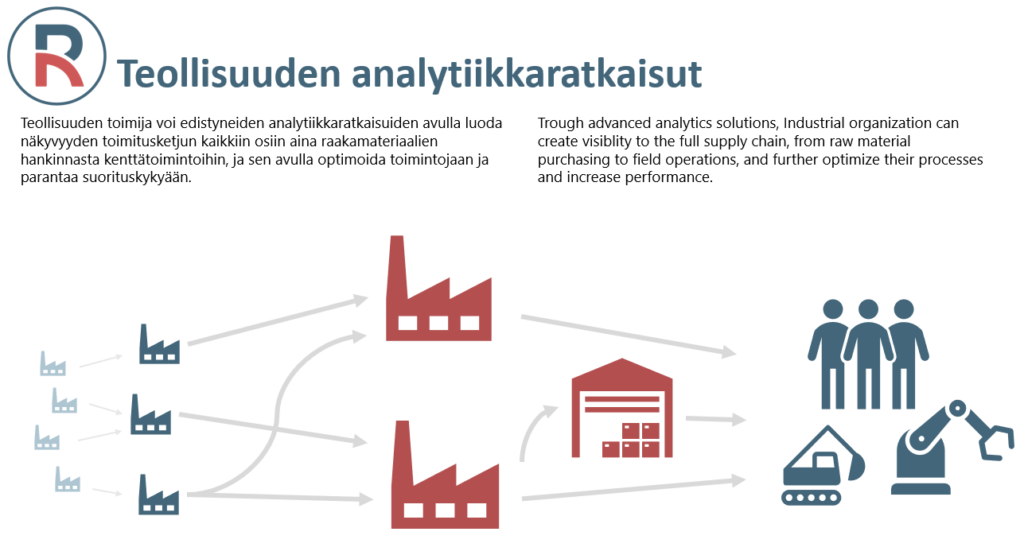

- Optimized Supply Chain: Data analytics provide a granular view of the supply chain, aiding in demand prediction, efficient inventory management, and risk mitigation associated with supplier reliability and market fluctuations.

- Enhanced Product Quality: By analyzing data across production stages, industries can spot anomalies, forecast issues, and sustain high product quality.

- Informed Decision-Making: Real-time data analysis paves the way for timely and informed decision-making, facilitating quick responses to market changes or operational issues.

- Increased Competitiveness: Data-driven insights unearth new business opportunities, spur innovation, and enable companies to maintain their competitive edge in the rapidly evolving industrial landscape.

- Risk Management: Analytics can spotlight risk factors, whether in safety, compliance, or finance, enabling companies to proactively manage and mitigate these risks.

- Sustainability: Through resource optimization and waste reduction, data analytics make industrial operations more sustainable and environmentally friendly.

- Customer Satisfaction: By better understanding and predicting customer needs, industries can enhance customer satisfaction and loyalty, thereby increasing their market share.

Investing in data analytics, bolstered by a robust data platform, can deliver substantial returns for industrial companies. By unlocking the power of their data, these organizations can usher in sweeping improvements across their operations.